You have new quote information.

View My Dashboard

×

-

Sign In / Register

-

-

Hello, {{vm.session.firstName}} My Account

Account Management

Profile Info

Customer

{{::vm.session.billTo.firstName}} {{::vm.session.billTo.lastName}}

{{::vm.session.billTo.companyName}}

Customer #: {{::vm.session.billTo.customerNumber}}

Sales Rep

{{::vm.session.properties.primarySalesPerson}}

{{::vm.session.billTo.email}} {{::vm.session.billTo.phone}}

-

-

My Cart ({{vm.cart.totalCountDisplay}})

-

Products

-

Equipment

-

Case SealingStretch Wrap SystemsContinuous Inkjet Printers

- Brands

-

Automated Packaging SystemsClamcoCombiEasteyFelinsFrommHighlightIntertape Polymer GroupKallfassLeibingerMoscaOrgapackGreenbridgePregisRobopacShanklinSquid InkStraPackStraub Design Company

- Custom Packaging

-

Inside the BoxOutside the BoxAerospace & DefenseEcommerce & FulfillmentElectronicsFood & BeverageIndustrial/OEM

- SSI Services

-

Proactive Inventory ManagementPackaging Assessment

- About Us

-

Overview

-

Protect Your BrandReduce CostsIncrease Productivity

-

Using Ink-jet Technology for Packaging EfficiencyOptimizing Packaging Operations with Portable Stretch WrapperCustom Packaging for Audio EquipmentMagnetic Tape Strips for Retail Display Graphics

- Products

- Equipment

- Brands

- Custom Packaging

- SSI Services

-

About Us

- Overview

- Packaging Profitability

-

Customer Success

- Using Ink-jet Technology for Packaging Efficiency

- Optimizing Packaging Operations with Portable Stretch Wrapper

- Custom Packaging for Audio Equipment

- Magnetic Tape Strips for Retail Display Graphics

- Protective Corrugated Pack

- Reducing Labor with a Hook & Loop Coins Solution

- Productivity Through Automation

- Manufacturer Reclaims Warehouse Space for Production

- Food Producer Eliminates Unplanned Downtime

- Custom Foam for Industrial Supplies

- Culture & Careers

- Packaging Papers

The

Packaging

PapersThe

Packaging

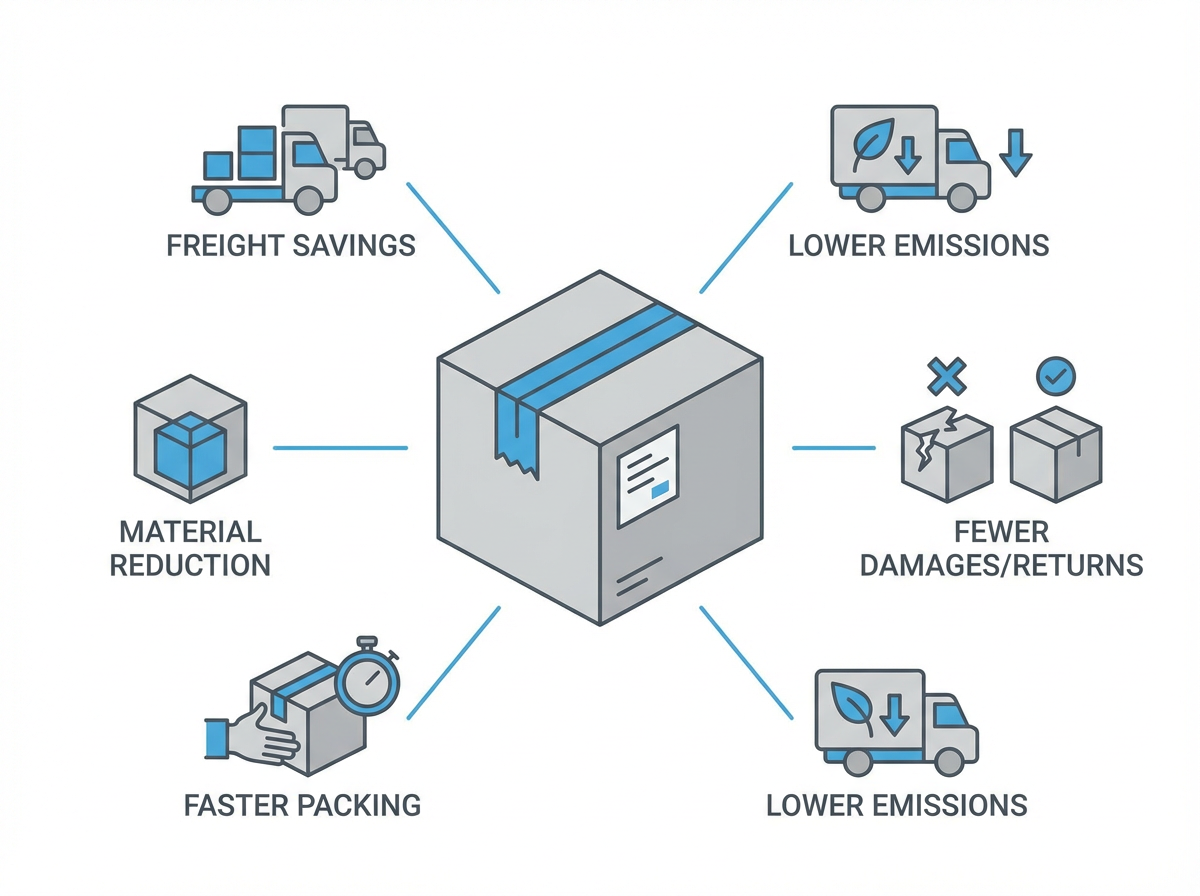

PapersSummary. Right-sized packaging boosts ROI by matching carton size to product dimensions while still protecting items in transit. When boxes are oversized, companies pay more in dimensional-weight freight, use more corrugate and void fill, waste warehouse space, and ship more “air” than product. Right-sizing reduces shipping costs, materials... spend, and damage-related returns, while improving throughput—especially with automation. Start with a packaging audit, redesign for fit plus protection, test under real conditions, and track freight, waste, and damage rates to confirm savings.Show moreThe ROI of Right-Sized Packaging

Right-sized packaging is the practice of designing cartons or containers to match as closely as possible to the dimensions of a product while also providing the necessary protection during handling and transit. This balance of dimensional efficiency and protective performance helps reduce costs, minimize waste, and improve supply chain efficiency.

When right-sizing is not applied, the excess space in packaging leads to higher freight charges, unnecessary material consumption, and increased environmental impact. Over-packaging also results in wasted void fill, inefficient use of warehouse space, and reduced load density in shipping.

Unnecessary Volume = Unnecessary Cost & Environmental Impact

A 2024 study in Circular Economy found that packaging material waste from e-commerce and delivery services is significantly driven by oversized cartons. This excess volume impacts both operational budgets and environmental performance by increasing the material that must be produced, transported, and disposed of.

The cost implications are twofold. First, freight costs rise when dimensional-weight pricing is applied to packages with excess air, as carriers charge for the greater of actual or volumetric weight. Second, material costs escalate when larger cartons require more corrugated board and void fill. These factors can also raise warehouse storage costs, reduce handling efficiency, and increase procurement spend.

Environmentally, oversizing consumes additional raw fiber and energy, while extra void fill—often plastics or foams—adds to landfill or recycling burdens. Larger packages also lower truckload efficiency, requiring more trips, burning more fuel, and increasing greenhouse gas emissions. In aggregate, this inefficiency amplifies a company’s carbon footprint and undermines sustainability goals.

Why Right-Sized Packaging Matters

- Freight Savings: Reducing unused volume in cartons lowers volumetric shipping charges, often leading to double-digit percentage reductions in freight costs.

- Material Efficiency: Smaller cartons require less corrugate and less void fill, reducing both purchase and storage costs for materials.

- Product Protection: Right-sized packaging limits product movement inside the box, lowering damage rates and reducing returns.

- Operational Gains: Automated right-sizing systems can produce cartons matched to order requirements, improving throughput and reducing packing labor.

- Sustainability: Smaller packages improve truckload utilization, reducing the number of shipments and associated greenhouse gas emissions.

How do I reduce waste and cost through right-sized packaging?

Here are a few key takeaways for packaging and operations teams:

- Measure before you change

Conduct a packaging audit to determine current cube utilization, material use, freight costs, and damage rates. - Design for both fit and protection

The goal is not the smallest possible box, but the smallest box that still provides the required protection. - Test for performance

Validate right-sized designs under real shipping conditions to confirm they meet handling and durability requirements. - Evaluate automation options

In high-volume or high-variability operations, automated right-sizing systems can improve consistency and speed. - Track and refine

Monitor material usage, freight costs, and waste volumes to verify ROI and guide future adjustments.

Sustainable packaging focuses on the full lifecycle, choosing materials and designs that fit the product. Real impact comes from smart optimization and clear guidance on reuse and recycling.

Additional Articles of Interest

Product Damage is the Most Expensive Problem You're Overlooking

Shippers Supply | Nov 5, 2025

Shipper’s Supply—Your Strategic Partner for Packaging Solutions

Shippers Supply | Oct 8, 2025

Unlocking Efficiency and Savings with a Packaging Assessment

Shippers Supply | Sept 10, 2025

Looking for Special Design Work to Fit a Unique Product or Challenge?

Let’s create a custom packaging solution that saves you time, money and headaches—starting with a quick conversation.

-