Looking for Special Design Work to Fit a Unique Product or Challenge?

Let’s create a custom packaging solution that saves you time, money, and headaches — starting with a quick conversation.

Customer

{{::vm.session.billTo.firstName}} {{::vm.session.billTo.lastName}}

{{::vm.session.billTo.companyName}}

Customer #: {{::vm.session.billTo.customerNumber}}

Sales Rep

{{::vm.session.properties.primarySalesPerson}}

In the fast-paced world of manufacturing, distribution, and logistics, securing palletized loads is a daily necessity. For many businesses, manual pallet wrapping is the default—but is it really the best choice? As companies look for ways to cut costs, improve efficiency, and deliver a better customer experience, investing in a stretch wrapper is rapidly becoming the smart, strategic choice for end-of-the-line automation. In fact, operations wrapping as few as 10 pallets a day can benefit from investing in a stretch wrapper.

If you’re on the fence about making the leap to automated packaging, this in-depth guide will walk you through:

Stretch wrap is a highly elastic plastic film, usually made of polyethylene (LLDPE). It is designed to stretch as it’s applied, then tighten again over time, firmly binding products together on a pallet. The film’s cling and tension hold everything in place, preventing shifting, collapse, and exposure to dust and moisture.

A stretch wrapper is a machine that's designed to wrap plastic stretch film tightly and evenly around a palletized load. The film’s elasticity allows it to cling to itself, holding products together and stabilizing them during storage and transit. Stretch wrappers come in a variety of types, from manual turntable models to fully automated rotary arm systems, making them suitable for businesses of all sizes and shipping volumes.

Before diving into the benefits of stretch wrappers, let’s take a closer look at the challenges of manual wrapping:

Now let’s explore how a stretch wrapper can transform your packaging process and deliver measurable value across your business:

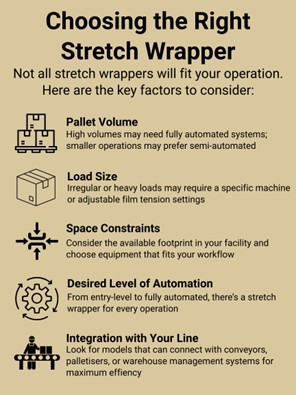

With so many models on the market, it’s important to match the equipment to your specific needs—otherwise you risk slowdowns, bottlenecks, or wasted resources. Here are the key factors to think about before you buy.

At SSI, we don’t just sell machines—we become your partner in packaging success. Our team will:

Even small to mid-sized businesses can benefit from the labor, material, and damage savings that stretch wrappers provide. The ROI often becomes clear within months.

SSI offers a wide range of models and can help you find the perfect fit for your operation, whether you handle standard pallets or irregular loads.

Modern stretch wrappers are built for durability and easy upkeep. With regular cleaning and occasional parts replacement, most machines will deliver years of trouble-free service. Check out our maintenance plans.

Yes! Many stretch wrappers have adjustable settings to accommodate varying pallet sizes, shapes, and weights. Depending on your needs, SSI can recommend machines with programmable controls or quick-change features.

SSI’s packaging experts will help you select the right film gauge, width, and type for your products and shipping conditions—ensuring maximum protection and cost savings.

Absolutely. SSI provides hands-on training for your team during installation, as well as ongoing support, troubleshooting, and refresher sessions as needed.

Most businesses see a return on investment within the first year, thanks to reduced film usage, fewer damaged shipments, and increased throughput. Some see a return within months!

Whether you’re considering automation or an upgrade, you don’t have to navigate changes alone. SSI is ready to help you transform your palletizing process

Investing in a stretch wrapper is about more than speeding up one task—it’s about protecting your products, supporting your team, and positioning your business for growth. With SSI’s expertise and support, you’ll be ready to meet today’s demands and tomorrow’s opportunities.

Let’s create a custom packaging solution that saves you time, money, and headaches — starting with a quick conversation.