You have new quote information.

View My Dashboard

×

-

Sign In / Register

-

-

Hello, {{vm.session.firstName}} My Account

Account Management

Profile Info

Customer

{{::vm.session.billTo.firstName}} {{::vm.session.billTo.lastName}}

{{::vm.session.billTo.companyName}}

Customer #: {{::vm.session.billTo.customerNumber}}

Sales Rep

{{::vm.session.properties.primarySalesPerson}}

{{::vm.session.billTo.email}} {{::vm.session.billTo.phone}}

-

-

My Cart ({{vm.cart.totalCountDisplay}})

-

Products

-

Equipment

-

Case SealingStretch Wrap SystemsContinuous Inkjet Printers

- Brands

-

Automated Packaging SystemsClamcoCombiEasteyFelinsFrommHighlightIntertape Polymer GroupKallfassLeibingerMoscaOrgapackGreenbridgePregisRobopacShanklinSquid InkStraPackStraub Design Company

- Custom Packaging

-

Inside the BoxOutside the BoxAerospace & DefenseEcommerce & FulfillmentElectronicsFood & BeverageIndustrial/OEM

- SSI Services

-

Proactive Inventory ManagementPackaging Assessment

- About Us

-

Overview

-

Protect Your BrandReduce CostsIncrease Productivity

-

Using Ink-jet Technology for Packaging EfficiencyOptimizing Packaging Operations with Portable Stretch WrapperCustom Packaging for Audio EquipmentMagnetic Tape Strips for Retail Display Graphics

- Products

- Equipment

- Brands

- Custom Packaging

- SSI Services

-

About Us

- Overview

- Packaging Profitability

-

Customer Success

- Using Ink-jet Technology for Packaging Efficiency

- Optimizing Packaging Operations with Portable Stretch Wrapper

- Custom Packaging for Audio Equipment

- Magnetic Tape Strips for Retail Display Graphics

- Protective Corrugated Pack

- Reducing Labor with a Hook & Loop Coins Solution

- Productivity Through Automation

- Manufacturer Reclaims Warehouse Space for Production

- Food Producer Eliminates Unplanned Downtime

- Custom Foam for Industrial Supplies

- Culture & Careers

- Packaging Papers

The

Packaging

PapersThe

Packaging

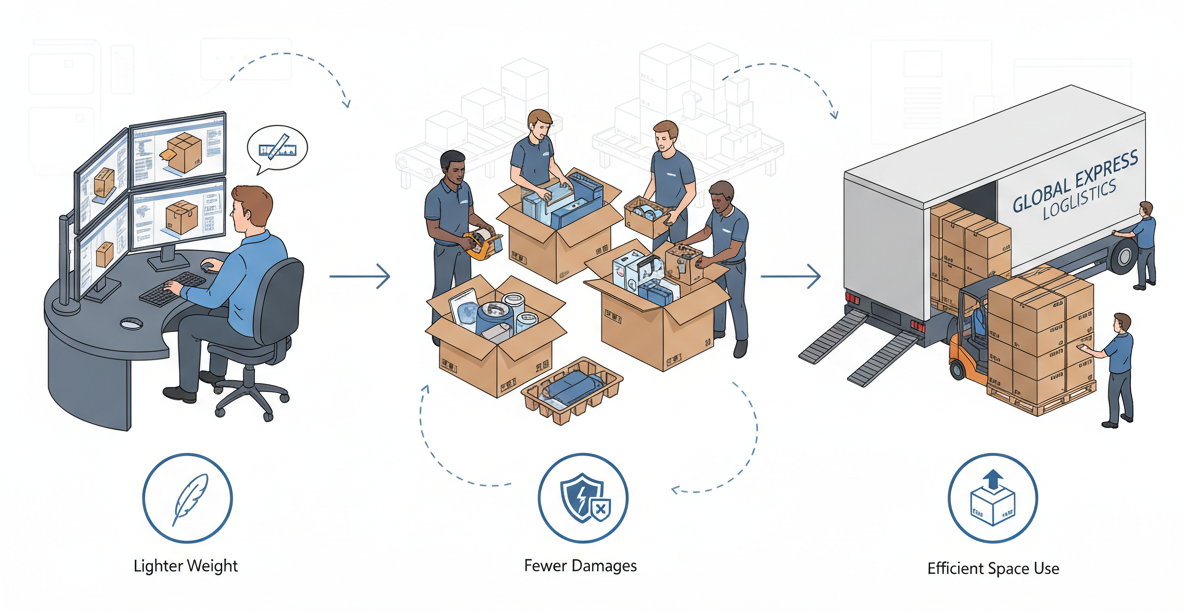

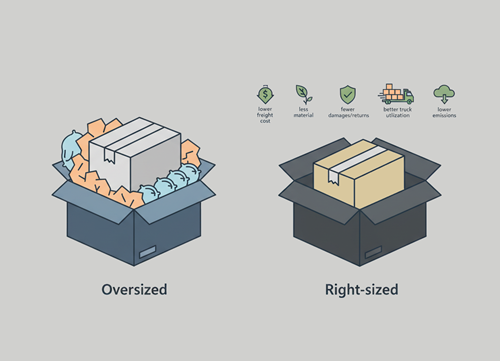

PapersSummary. Smart packaging turns a common cost center into a performance advantage. When packaging is engineered early alongside products and operations, you can right-size cartons, reduce damage, speed pack-out, and lower freight spend. Aligning custom design with the right equipment, from case sealers to stretch wrappers, compounds those gains... with consistency and throughput. A focused packaging assessment helps uncover hidden costs in labor, floor space, and materials, so you can upgrade strategically and take control of packaging without rebuilding your entire operation.Show moreTake Control of Your Packaging

For many companies, packaging is treated as an afterthought. But the truth is, packaging affects nearly every part of your business: your customer’s first impression, your production line speed, your labor costs, your freight spend, and even your brand perception. Smart packaging isn’t just a matter of materials. It’s a lever for cost control, efficiency, and brand value.

Getting ahead of your packaging process doesn’t require a full operational overhaul. It just means thinking holistically. When you involve the right partner early—especially one that brings custom design expertise and access to proven materials and equipment—you unlock smarter packaging strategies that enhance performance, improve the customer experience, and deliver measurable savings.

Why Early Involvement Pays Off

When packaging is considered at the product planning or operational design stage, it opens up opportunities to:

- Optimize dimensions for freight efficiency

- Reduce material waste and damage risk

- Improve unboxing and user experience

- Align packaging with your brand identity

- Speed up pack-out with better ergonomics

- Create tailored solutions for unusual or high-value products

Even small design changes like customizing inserts, switching foam layouts, or right-sizing corrugated can translate to faster packing, fewer returns, and reduced total cost of ownership. Starting with a custom solution avoids retrofitting later and allows you to engineer every step of the process for efficiency.

Design + Equipment = Efficiency That Scales

Once the packaging design is dialed in, fulfillment execution becomes the next lever for savings. That’s where automation and layout planning can have an outsized impact.

Packaging equipment like stretch wrappers, case sealers, and labelers can:

- Cut labor hours significantly

- Free up valuable floor space

- Standardize consistency and reduce errors

- Enable higher throughput with less physical strain

But the real value comes when these tools are aligned with your custom packaging design. A partner with engineering, equipment, and inventory capabilities can build packaging and workflows that fit together seamlessly without relying on guesswork or off-the-shelf compromises.

A Full-Process Partner Makes It Easy

Working with a single-source packaging partner brings everything together. From structural engineering and material selection to automation recommendations and restock support, you benefit from cohesive planning and execution that works the way your business runs.

Whether you’re launching a new product or optimizing a mature line, your packaging partner should help you:

- Identify hidden costs in labor, space, freight, and damages

- Design custom packaging that solves real-world protection and workflow issues

- Implement packaging equipment that amplifies labor and cost savings

- Deliver repeatable, scalable solutions that match your operations

How do I take control of packaging without starting over?

- Start with a packaging assessment. Look for hidden costs in labor, floor space, damage rates, or oversized packaging.

- Evaluate where customization creates leverage. The right structural design can improve every downstream step.

- Explore packaging automation—even midstream. You don’t need to start from scratch to justify new equipment.

- Choose a partner that brings it all together. Custom packaging, materials sourcing, and equipment planning should all align for maximum return.

Take control now. Smarter packaging is more than a box—it’s a better business strategy.

Looking for Special Design Work to Fit a Unique Product or Challenge?

Let’s create a custom packaging solution that saves you time, money and headaches—starting with a quick conversation.

-