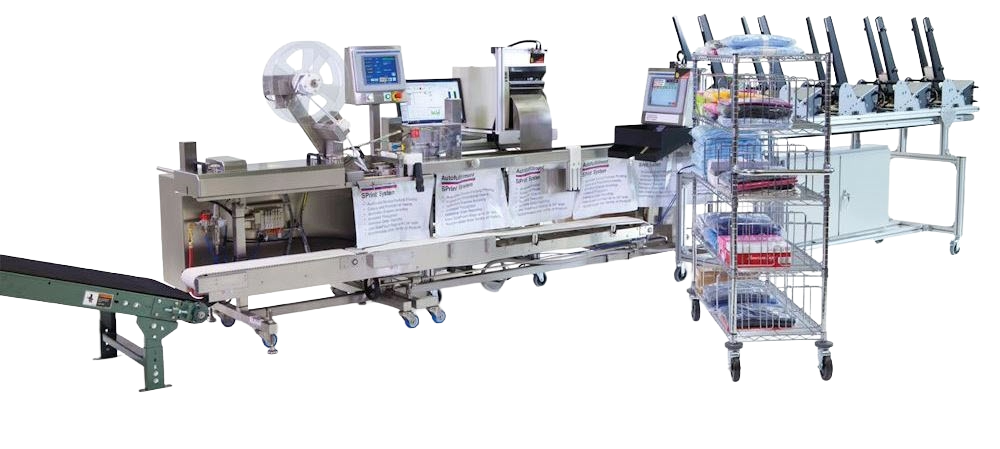

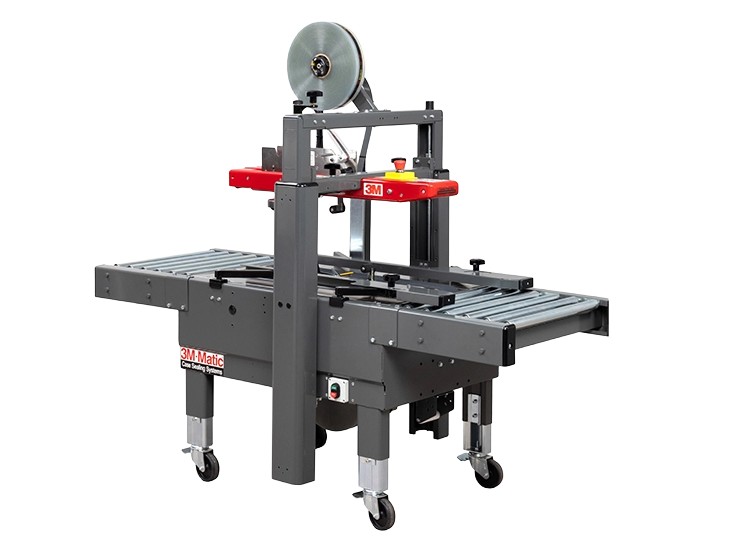

Innovative Packaging Equipment

Whatever your packaging challenges, we help you find the right solution. At SSI, we are specialists. If you are looking for packaging solutions and you don’t know where to start, SSI will provide the strategic guidance you need. Whether you are looking to increase productivity, improve processes, control quality, or lower costs, the SSI team of experts is here to help you find the best equipment available for your unique needs. We have partnered with the most innovative, reliable and diverse manufacturing brands in the industry to bring you the most complete solutions to help you support and grow your business.